Steffen Dieckmann

Key Account Manager Industry

Customer focus coupled with market trends: At Poppe, new products are always developed in close cooperation with our customers. The concepts we develop for specific requirements are a response to the latest market trends and offer unconventional solutions.

Versatility is our strength – As a long-standing partner of the automotive industry, we see ourselves as a solutions-oriented development service provider. Innovative process technologies allow us to manufacture individual single-component and multi-component profiles for vehicle interiors, exteriors and engine compartments. With a wide range of assembly and finishing options, we add real value to our customers’ products.

An extensive range – Profiles are used in almost every area of industrial applications. Poppe Elastomertechnik GmbH’s product range extends from simple protective profiles consisting of a single-material component through to complex switching profiles involving up to three-material components.

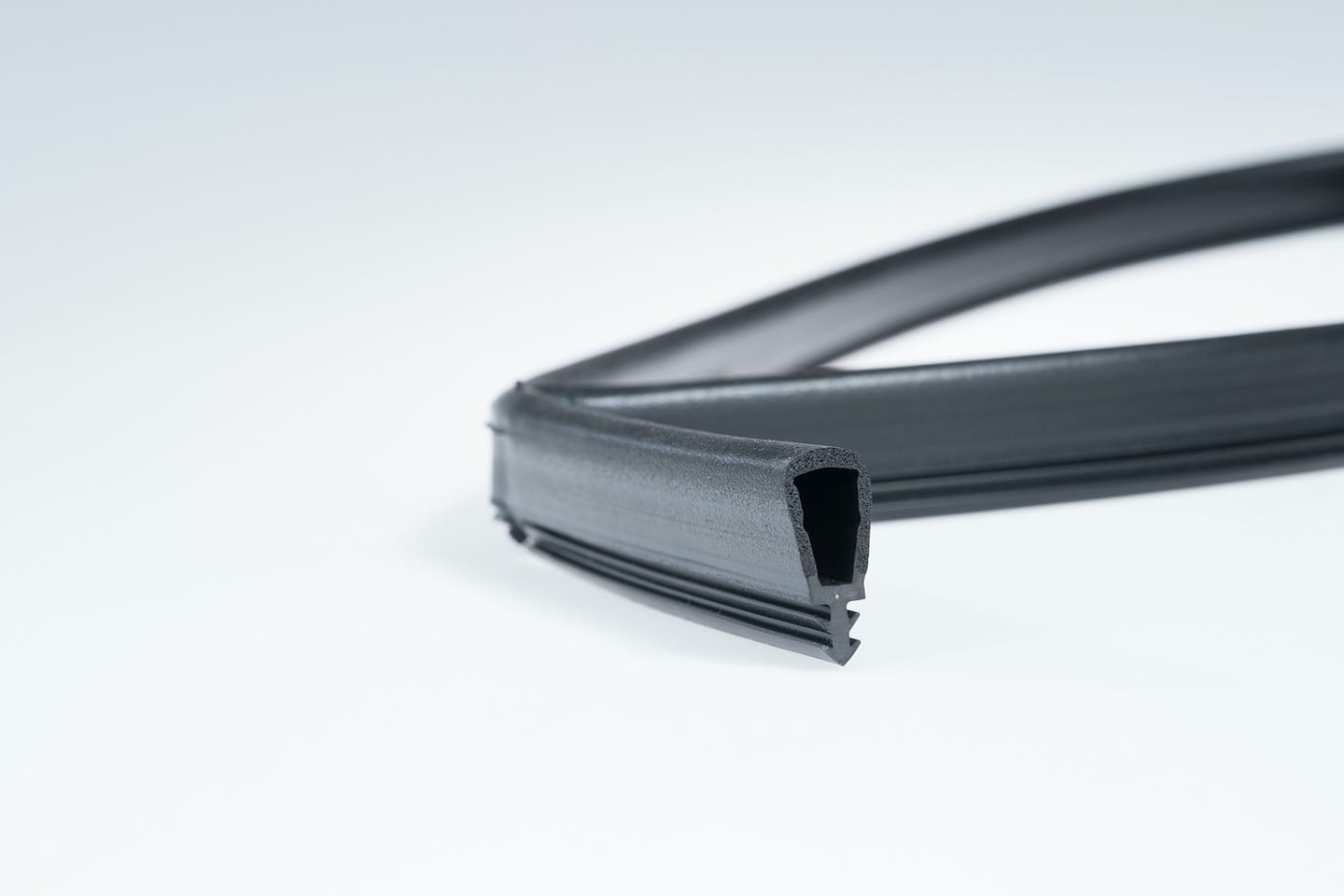

Thanks to intelligent material combinations, Poppe door and gate profiles comply with the required sealing function as well as performing security-relevant functions. Our production technologies allow us to manufacture door and gate profiles in every dimension category – from 20 g to 3,000 g per meter.

Poppe rail profiles are used for numerous applications within the rail industry, including as window profile frames, finger protector profiles and door profiles in local and long-distance passenger rail transport Our proprietary materials – certified in accordance with EN 45545-2 – allow us to develop high-end profiles in accordance with strict quality standards. Window profile frames are made using state-of-the-art injection moulding.

Innovative production technologies allow us to manufacture precise, high-quality profiles for applications such as wind turbines and solar systems. In-house material development enables us to manufacture long-lasting profiles that can withstand high stress, e.g. for wind turbine roller bearings.

Poppe multi-components are used in buses for applications such as window profile frames and semitrailer and hatch seals. Innovative production techniques allow us to achieve the continuous production of wheel arch brushes, among other things.

Poppe’s sealing profiles ensure the reliable performance of equipment such as sensitive length gauges in mechanical and plant engineering. We comply with high standards in terms of tolerance and dimensional accuracy using intelligent production techniques in the area of continuous and non-continuous vulcanization.

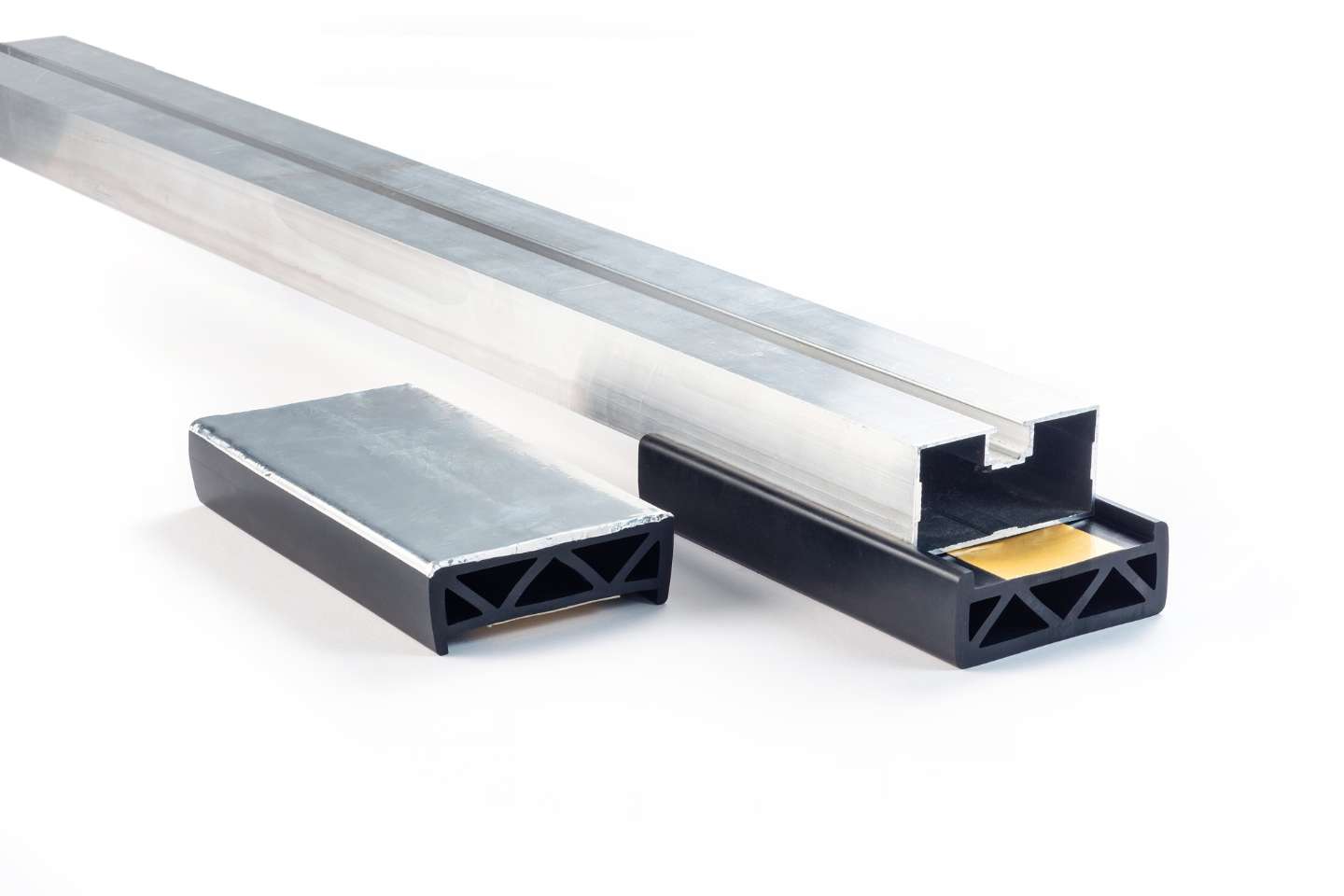

EPDM profiles as damping elements for photovoltaic systems offer a high-grade alternative to conventional building protection mats – individually designed (e.g. for “clipping” into a rail), they allow easier and faster installation on site. By processing weather and UV-resistant material, we manufacture extremely durable products that also meet fire protection requirements in accordance with DIN ISO 4102 B1.

Key Account Manager Industry

Customer Service Industry

Poppe engine hood seals are synonymous with innovative product design and application-specific material development. Among other things, they play an essential role in stable thermal management in the engine compartment and prevent exhaust gas and vapor from entering the vehicle’s fresh air system.

Water tank seals are used for the targeted drainage of rainwater, meltwater and washer fluid from the windshield. The main aim is to prevent exhaust gas and vapor from entering the fresh air system. Thanks to our wide range of process technologies and our broad portfolio of materials, we are involved in water tank development right from the start.

Poppe’s media-carrying hoses offer a high degree of precision in terms of dimensional accuracy and roundness. Specialty production techniques allow us to achieve the most sensitive tolerances and manufacture hoses with small wall thicknesses. In addition to manufacturing simple hoses, our portfolio extends to include the attachment of injection-moulded parts as connectors to the hose fittings.

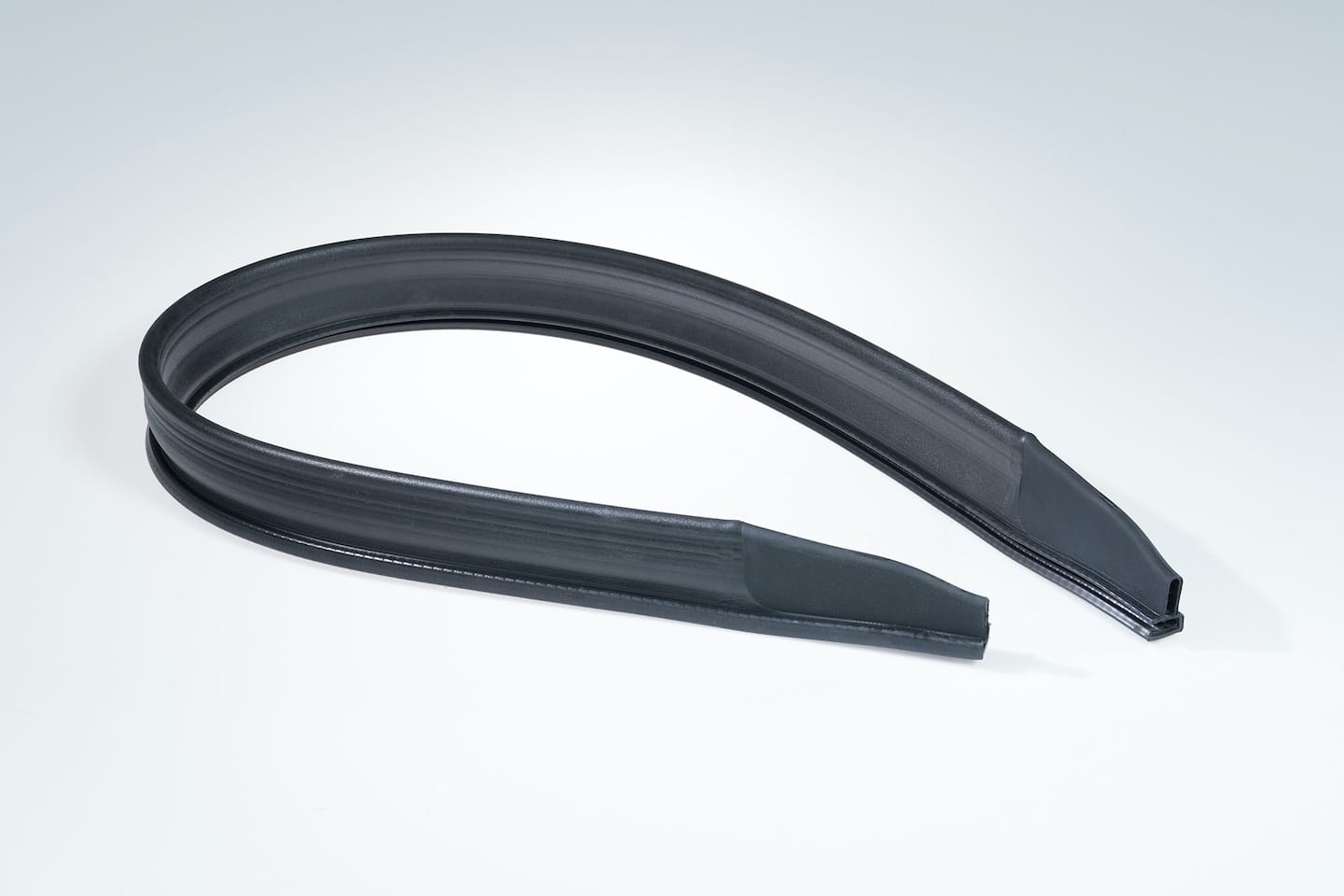

Poppe door joint seals are used to protect the entrance area of the vehicle against dirt deposits and to absorb driving noise, thereby increasing passenger comfort. Thanks to our intelligent design concept combining sealing and mounting functions, we are positioned as a reliable development partner for the automotive industry.

Although not in sight, water drain hoses play a major role in ensuring the functionality of the sunroof and passenger comfort. The water drain hose, which is partially integrated into the body shell, directs rainwater, meltwater and washer fluid from the sunroof system to the wet area of the vehicle (e.g. the wheelhouse) quickly and silently.

Automobiles use a large number of electric motors. Poppe coupling elements play a vital role in dampening or eliminating the sound of these motors starting up. Precision production techniques mean we can ensure a high degree of dimensional accuracy. Additional machining allows us to achieve the most sensitive tolerances for function-relevant parameters.

Poppe power window inserts ensure that side windows sit safely and securely in the power window mechanism. Customer-specific contour die-cutting enables the optimal integration of our power window inserts into the customer’s assembly process.

Poppe adhesive pads are used around the world as vibration dampeners or distance holders. Assembly using various types of adhesive tape enables optimal adaptation to the substrate of the adhesive pad. Our services include preassembled mounting kits with exactly the right quantities of adhesive pads (kiss cutting) and ensuring optical detection.

The doors of a vehicle are opened and closed several thousand times during their lifecycle. This places considerable strain on the door locks. Poppe door lock bumpers dampen the mechanical lock and absorb locking sounds – consistently throughout the entire vehicle lifecycle.

Key Account Manager Automotive

Key Account Manager Automotive

Key Account Manager Automotive

Account Manager Automotive

.