LSR MOLDED PARTS

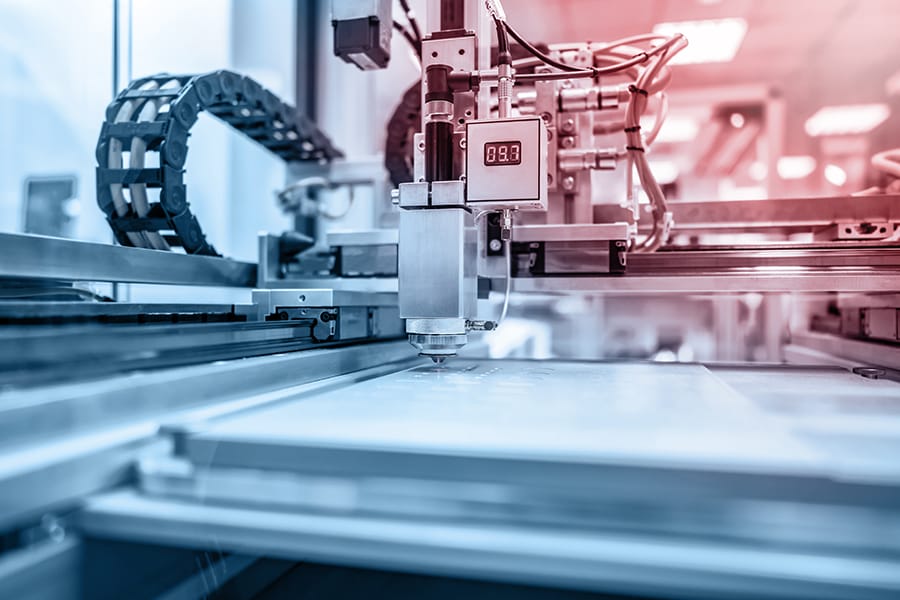

At our Gelnhausen facility, we manufacture serial products from over 100 molding tools for our broad range of LSR articles. With the outstanding properties of LSR (Liquid Silicone Rubber) and modern injection molding systems, Poppe offers fully automated operation of large-scale production in numerous automotive applications and in the sanitary and electrical industries, as well as in household appliances, food technology and railway vehicles.

Our production takes place on injection molding machines using the IM process. We process LSR and corresponding thermoplastics.

Highest Quality Automotive LSR parts: Made to Fit

We manufacture high-quality and precise components made of LSR for our customers in the automotive and industrial sectors. From sketches to serial production, from standard products to customized solutions, we are a reliable partner with over 100 years of experience in the production of rubber and silicone parts. Over 200 companies rely on our skills.

✓ Start co-engineering within 24h

✓ Multi-Component Processing

✓ Designed, developed and made in Germany

✓ ISO (9001-2015) & IATF certified

Curious about our quality? See for yourself!

Start co-engineering within 24h

Multi-Component Processing

Designed, developed and made in Germany

ISO (9001-2015) &

IATF certified

LSR Automotive and General Industry

Made to fit

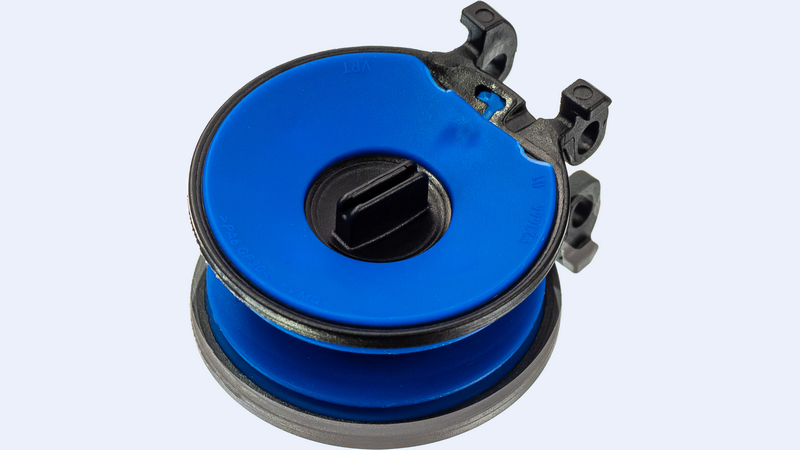

Automotive

LSR is increasingly used for automotive applications, mainly for parts like connectors, electronic housings and fluid handling devices. The outstanding material characteristics of LSR make it the perfect choice.

Poppe is a long-standing partner and supplier in the automotive industry, we have all relevant certifications such as IATF and possess all material and R&D know-how, and have highly automated processes.

General Industry

LSR is also discovered by many other industries as a reliable and versatile material for high-precision products.

We can co-engineer customised solutions, but also provide a production according to your drawing (build-to-print). All our activities are based on ISO 9001. From the design of individual high-tech solutions to advice on the selection of the right material for your products - we go the distance together until it fits.

Other industry?

We’re always on the lookout for new applications and industries for our technology. We invite you to challenge us with any ideas regarding our products or your industry.

Our clients

We're proud to have built lasting relationship with clients that can call themselves industry leaders in the automotive industry (OEM and TIER) and the general industry. Without bragging too much, we're like to share that we're quite excited to see our rubbers at...

LSR: one material – endless possibilities

LSR stands for Liquid Silicone Rubber. It combines outstanding material properties with flexible, precise and high-quality application possibilities. Here’s why we are the greatest fans of LSR:

- Stable & Constant:

Heat stability up to +180°C & cold flexibility down to -50°C. Constant properties, mechanical and electrical, over a wide temperature range.

- High electric insulation:

LSR is a perfect choice for electrical insulation.

- UV, weather and aging:

LSR is weather-proof and UV resistant. LSR has an excellent aging behavior.

- Colour & Transparancy:

We offer endless possibilities in transparency & colouring options.

- High gas permeability:

Gas permeability several times higher compared to other elastomers.

- Highly durable rubber:

LSR is one of the most environmental friendly rubber options, with optimal environmental compatibility.

Order your free sample box

Convince yourself of our quality and get your free sample box with the following sample items:

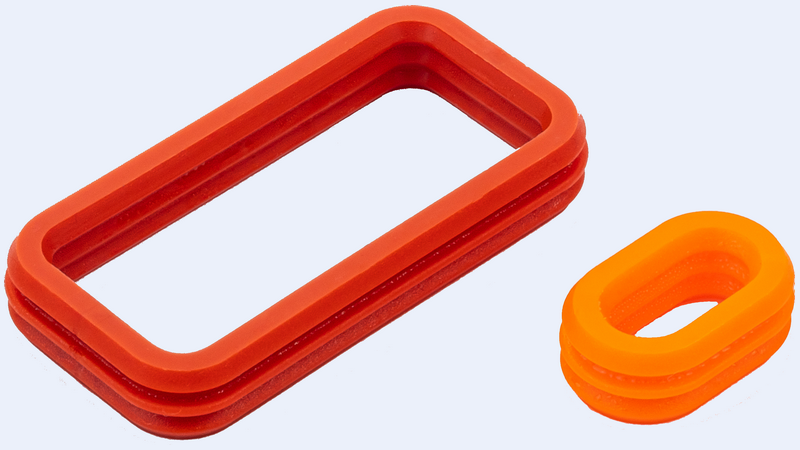

- LSR samples in 1c and 2c

- Multiple seals

- Various profiles

- Different O-rings

- A selection in various colors

standard or customized?

We provide what you need

Customized for you

We have the know-how to develop sophisticated LSR products according to individual standards and requirements. We cooperate closely with our customers' development departments to develop perfectly fitting LSR solutions. Challenge us, send us your ideas, we make the best out of all elastomers.

Standard, but excellent

Our standard LSR products meet the highest quality requirements and are used successfully by our customers in a wide range of industries. Our products are developed and produced in Germany according to the latest standards. We offer a wide range of materials and designs. And if something needs to be customized, we can of course do that too.

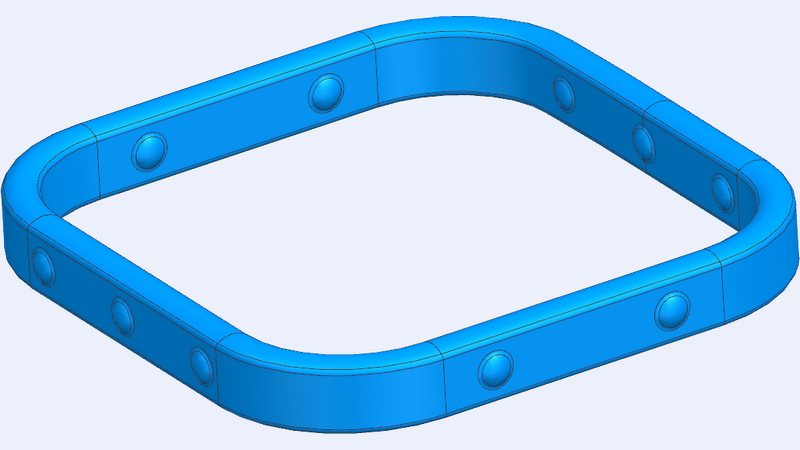

Moulded LSR Products

The number of parts being ceated with LSR, are innumerable. Here´s a small selection of LSR parts that we are producing for our customers. Besides more standardized parts, we are excelling in the production of custom parts. Please, feel free to contact us with your actuall technical challenge.

Custom Products

Co-engineering for 1C, 2C, 3C or even +C products according to customer requirements.

How we work? Order your co-engineered LSR in 3 steps

1. Your request

Share your request with us by filling out the form.

2. Contact within 24h

We'll contact you within 24h to discuss your demands and the need for co-engineering.

3. Start production

Starting production, receiving samples and scaling up production!

You know, broadly speaking, what you need and are just looking for the best provider? Then let's talk.

✓ More than 100 years experience

✓ Tier-1 player with international reputation

✓ Highly innovative production processes

Your contact person

Tobias Pawlak

Key Account Manager LSR Seals Automotive