Tobias Pawlak

Key Account Manager Automotive

Poppe Elastomertechnik GmbH is the brand-leading development partner and supplier of rubber spacers in the automotive industry. Our products have a wide range of uses, they are used as spacers and damping rings or as cable connectors on, for example, metal, steel flex, rubber or plastic cables/hoses. Other areas of application are mechanical engineering and electrical engineering. Detailed information is available in our ClipFix® product overview or by contacting us directly.

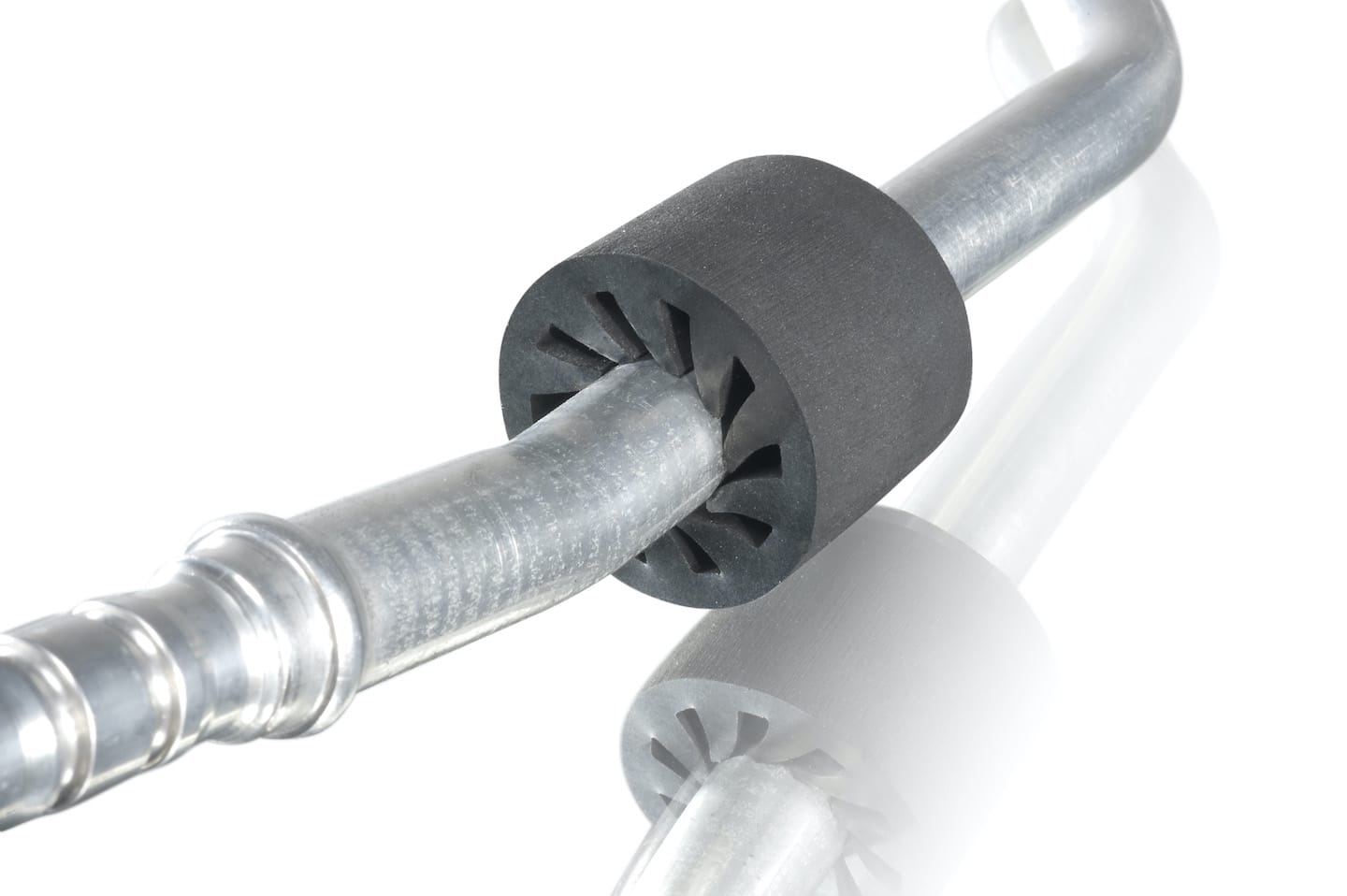

The “toothed ring” is the basic model in our ClipFix® product range, which has been used successfully within the automotive industry for decades. The ring has extremely good dampening properties, and its teeth mean it offers optimal tolerance compensation and heat insulation. The teeth ensure easy assembly and a firm fit. Our standard materials are EPDM and NBR. We can also offer silicone for custom models that need to be resistant to high temperatures.

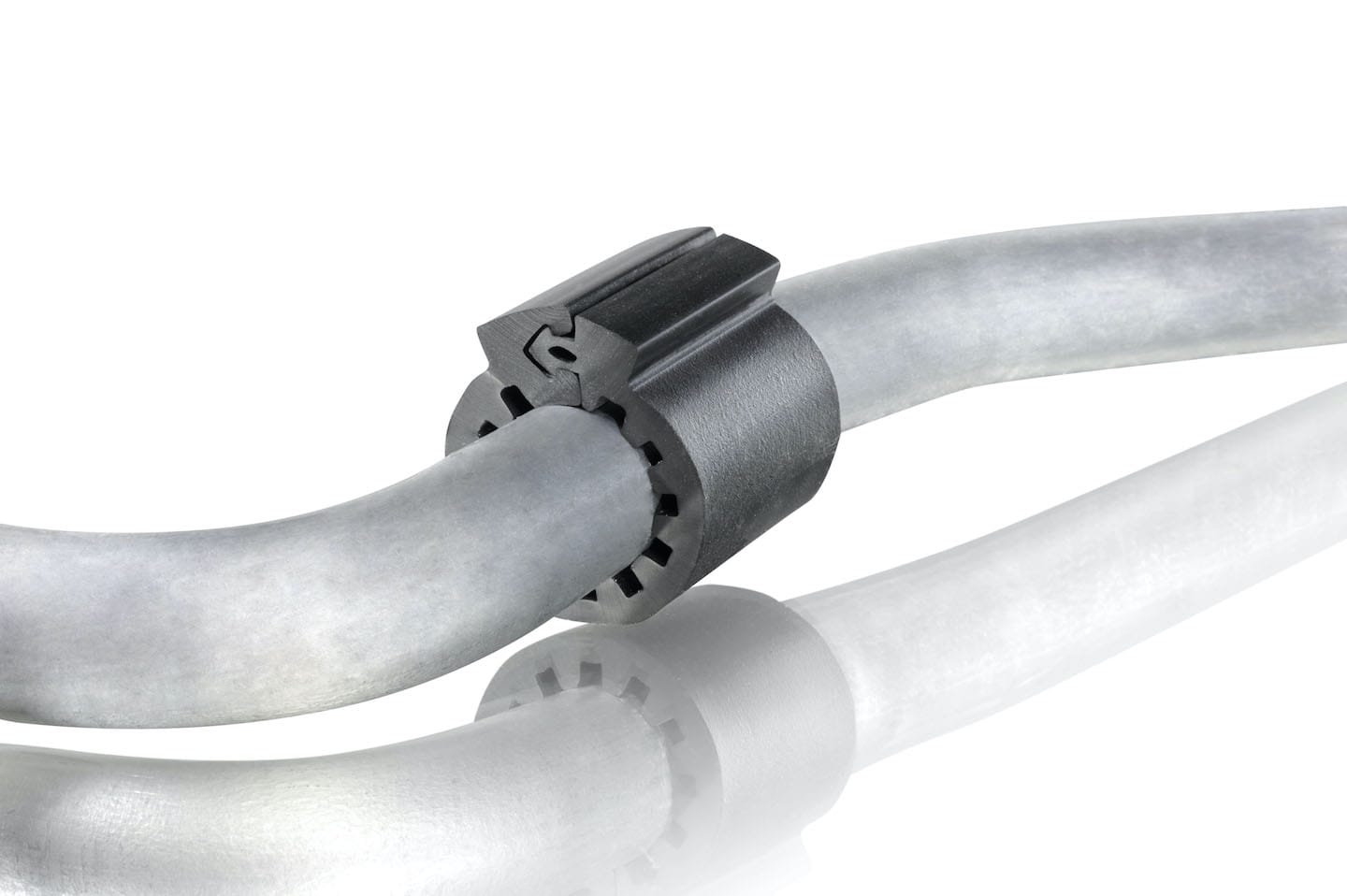

ClipFixbasic®, ClipFixcycle® and ClipFixtwins® are enhancements of our basic model. These products are fastenable and are particularly suitable for subsequent mounting, particularly in hard-to-reach places. Key features include repair-friendly handling, adhesive-free mounting and simple dismounting.

These ClipFix® rings are made from a dual-component EPDM material: A hard part for the fastening to ensure flawless locking and a soft body to provide the desired dampening effect. This feature is also offered by our “double-toothed clip rings”.

Our ClipFix® twins combine several cables or hoses and are primarily used as brackets and spacers. Custom dimensions developed specifically for our customers can be found in our ClipFix® specs catalog.

We continuously adapt our products to new requirements and changing market conditions. Particularly with regard to the development of modern electric vehicles, it is important to break new ground in material development.

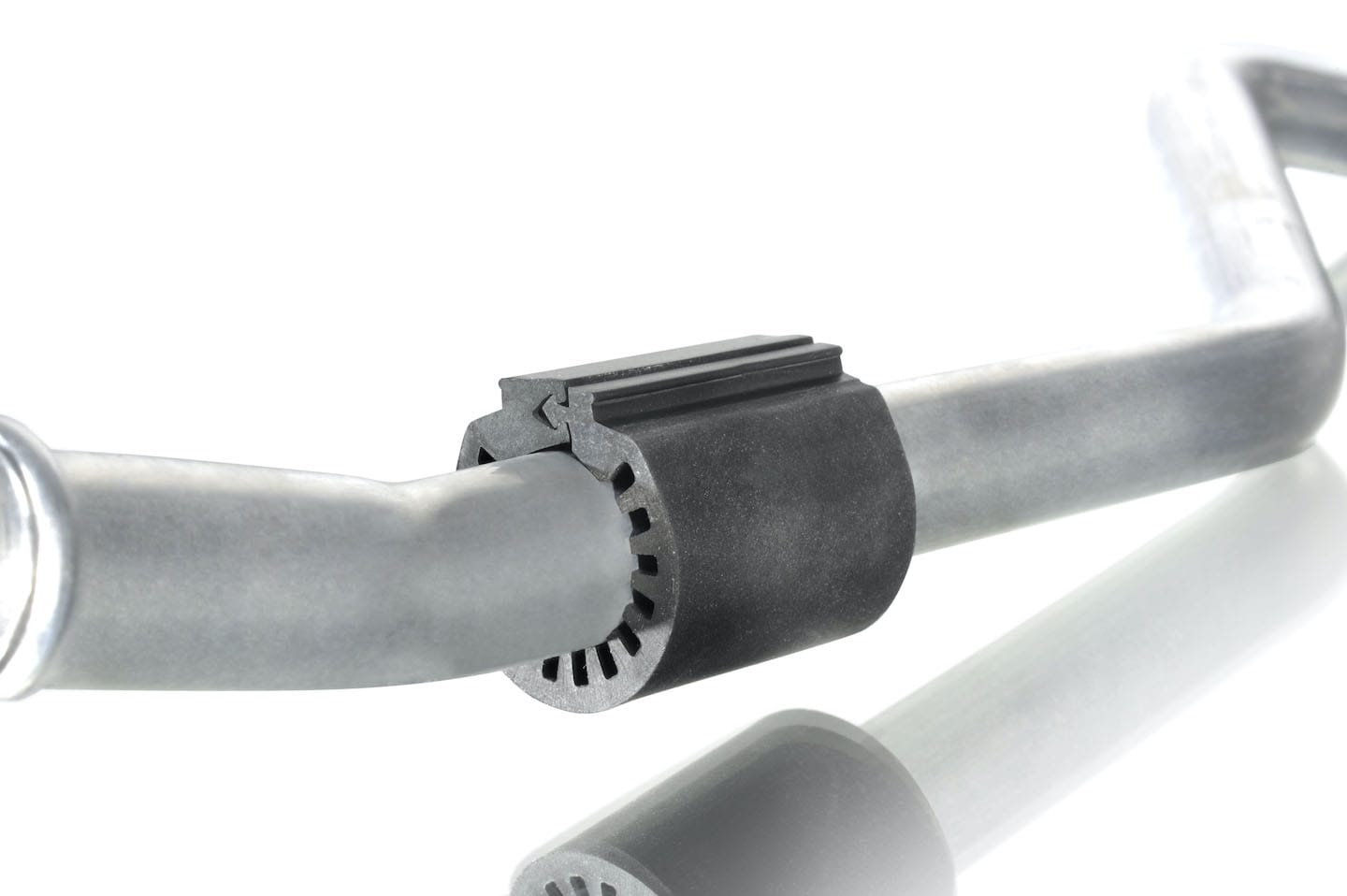

Electric motors are significantly quieter than conventional combustion engines. The perception of noise in the passenger compartment is therefore becoming even more important and the topic of NVH (Noise Vibration Harshness) is becoming increasingly important. With the aim of further optimizing the vibration and acoustic behaviour of vehicles, we have developed a microporous EPDM material.

The new material offers optimized vibration compensation and improved damping properties with improved elongation at break. Thanks to this flexibility of the material, we achieve a higher tolerance compensation with the microporous EPDM, so that one product, in one dimension, can be installed in hoses and cables with different outer diameters.

Modern vehicles are trimmed for efficiency in every detail. When it comes to reducing emissions and battery mileage, every gram counts. Our ClassicFix®micro and ClipFix®micro products offer a noticeable reduction in weight. By using spacers made of microporous EPDM, gram-for-gram savings can be achieved at various points. The reduced use of materials also conserves resources, improves the good material properties in terms of sustainability and reduces the carbon footprint.

The ClassicFixbasic® is the basic model of our Tube Line Wire – Protection Systems and offers you the following advantages:

Product characteristics:

We design further dimensions according to your wishes and requirements.

The ClassicFixmulti® is suitable for different pipe diameters and offers various advantages:

Product characteristics:

We are glad to implement additional dimensions for you.

With the ClassicFix®micro, we also offer the basic model of our Tube Line Wire – Protection Systems in a lightweight but durable version in microporous EPDM.

Product characteristics:

We also offer the microporous version in numerous dimensions – but we can also manufacture it entirely according to your wishes and requirements.

The ClipFixbasic® provides several benefits:

Product characteristics:

We look forward to developing further dimensions according to your individual requirements.

The unique features of ClipFixcycle® significantly simplify processing:

Product characteristics:

We design further products individually to meet your particular needs under due consideration of the available space.

ClipFix®micro provides the proven characteristics of a hard material for the clip in combination with the new, microporous material for the body.

Product characteristics:

We are happy to develop and manufacture other dimensions according to your individual wishes and requirements.

The ClassicFixtwins® and ClipFixtwins® protect two tubes simultaneously and moreover provide additional advantages:

Product characteristics:

We are glad to assist you with the development and implementation of distance holders for the assembly of your tubes.

* The producibility depends on both dimensions and has to be evaluated in the request case.

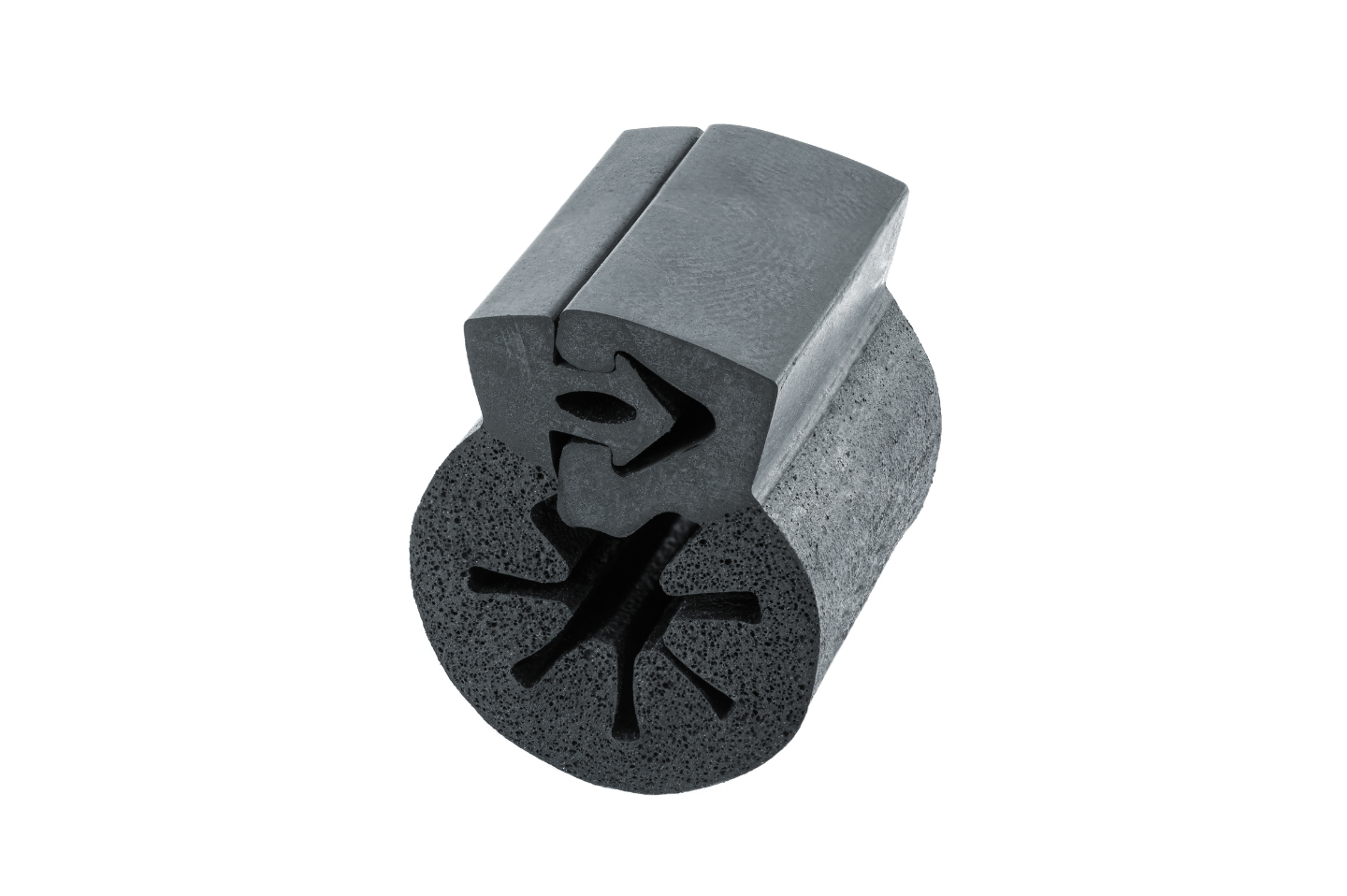

In addition to the dimensions listed in our brochure, we manufacture customized versions based on your individual requirements. The cross sections illustrated below give you a first impression of special dimensions we have produced so far.

Design, dimensions, wall thicknesses and lengths are developed individually and in close cooperation with you. Save time and money. Contact us!

Key Account Manager Automotive

Account Manager Automotive